Discover insights into the mitigation of blasting-induced vibrations and the importance of precise delay times between blastholes, with O-Pitblast Products

Blasting is a cost-effective energy source for rock breakage, so has expected surface mining operations involves the detonation of large explosive charges within blastholes, ranging from a few to hundreds or even thousands of blastholes. With the proximity to Residential and structural areas, mitigating the impact of blasting-induced vibrations is critical. The blast effects might include a change in the rock’s behavior having implications on the stability and integrity of structures (Kumar et al., 2016).

Choose the best Blast Pattern

The use of various firing patterns aims to balance efficient rock production and minimal external disturbance. Typically, surface mining employs millisecond delays for explosive charges, utilizing electric, non-electric or electronic detonators. Achieving optimal delays necessitates a blast design software and on-site measurements to validate simulation models and account for specific geological and mining conditions.

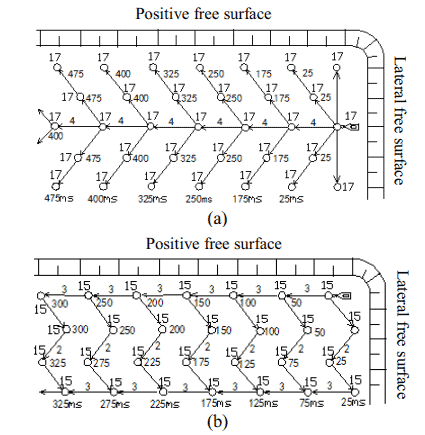

Hundreds of studies and methods for vibration control have been developed over the years. Procedures such as usage of deck charges and delay times between decks, decoupled charges and splitting the bench into more benches, and reducing the amount of explosive charge per blast hole were well accepted by the mining community (Persson et al. 1994, Langefors & Kihlström 1978).

Optimize the Blast Sequence

However, the use of proper delay times between blastholes became the most popular way of reducing the PPV prediction. The research initiated in 1950s into the possibility of disturbing the energy of explosives over time, enabled the recognition of possibilities of different delays promoting the most favorable fragmentation of rocks while minimizing the influence of blasting works on the structure surrounding the area. Report of Investigation 6151 indicates the first technical conditions (8 ms criterion) of conducting millisecond delay blasting, and the conclusions drawn there, in many aspects are still valid, or lead to further research.

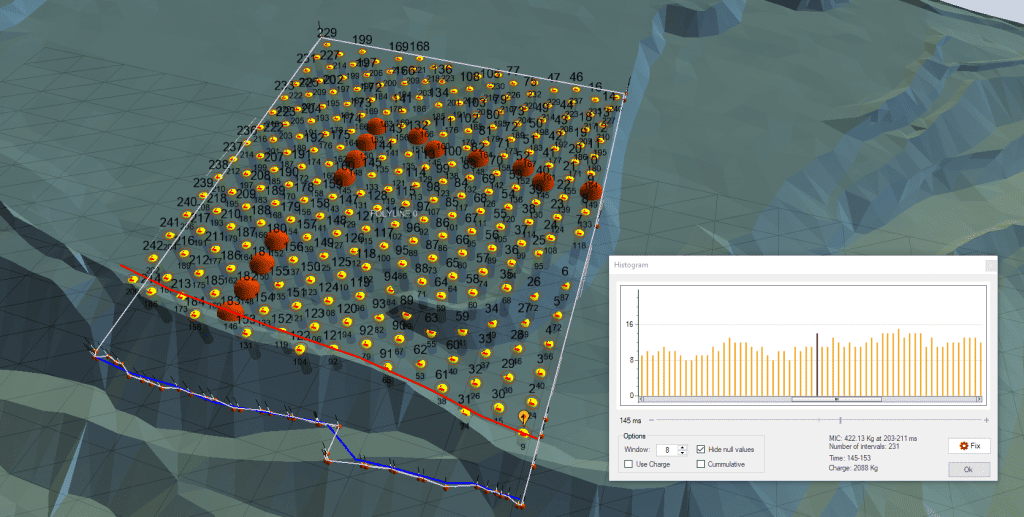

The digitalization has brought us blast design software, like the O-PitSurface, giving a whole new perspective. The O-PitSurface, when using electronic detonators, can help you chose the right delay between holes, maintaining the fragmentation and reducing the MIC, subsequently reducing the predicted PPV (Peak Particle Vibration).

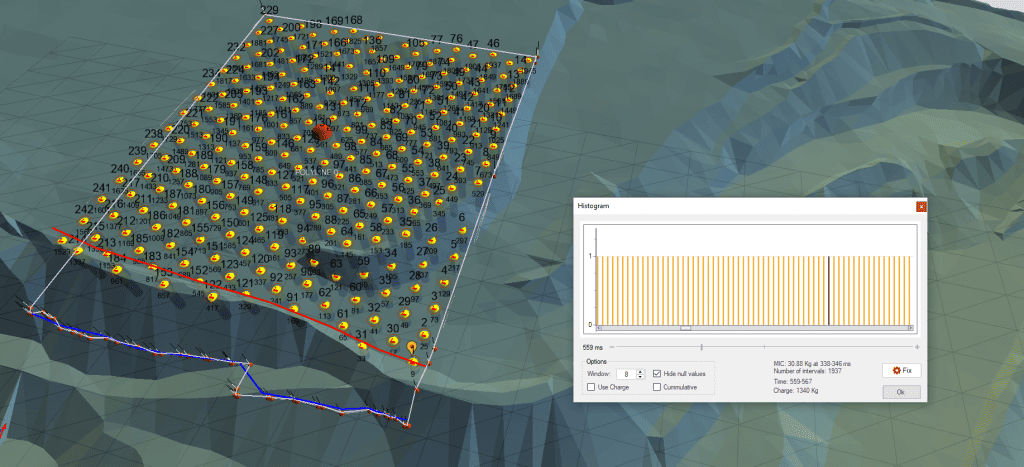

With the option “fix” you can, automatically correct the timings so that you only have one hole to detonate at a specific time. Consequently, reducing the Maximum Instantaneous Charge (MIC) and reducing vibrations.

With the option “fix” you can, automatically correct the timings so that you only have one hole to detonate at a specific time. Consequently, reducing the Maximum Instantaneous Charge (MIC) and reducing vibrations.

In conclusion, doe to all the studies and digitalization we can for see many potential issues, without having to do the blast. In this case we can have predictions of vibrations for the designed blast, giving us opportunity to alter parameters that can cause the vibration to decrease.