Blasting Practices and Safety

When it comes to mining operations, blasting is an essential practice used to break down rock material. While blasting is a necessary process, it also comes with a high degree of risk and requires extreme precision to avoid accidents. That’s why implementing robust safety measures during blasting is critical to ensuring the well-being of workers and maintaining operational efficiency.

- Risk Mitigation

One of the most critical parts of blasting in mining operations is mitigating the risks associated with the process. A risk assessment should be conducted before any blasting is carried out to identify potential hazards and develop risk mitigation strategies. This can involve identifying safe blast areas, using the appropriate explosives for the job, and ensuring proper storage and handling of explosive materials.

- Proper Equipment Usage

The types of equipment used in blasting are as important as the safety measures themselves. Operators must use the appropriate equipment for the job. By ensuring that workers are trained to operate and maintain the equipment properly, the chances of equipment-related accidents are reduced.

- Blast Area Monitoring

Blast area monitoring is another crucial aspect of safe blasting practices in mining operations. Workers must ensure that the blast area is clear of personnel, equipment, and unauthorized personnel to prevent any accidents. Monitoring blast vibrations and air overpressure levels can also help to mitigate any adverse impacts of blasting on the surrounding environment.

By implementing these blasting safety measures, mining operations can reduce the risks associated with blasting, promote worker safety, and maintain operational efficiency.

Engineering Controls for Safety

Engineering controls are critical to maintaining safety in open pit mining operations. These controls involved the design and implementation of stable slopes, the use of structural supports, and monitoring systems to detect and minimize hazards.

- Slope Stability

One of the primary hazards in open-pit mining is slope instability. Unstable slopes can lead to dangerous rockfalls and even catastrophic slope failure. Ensuring the stability of slopes requires careful design and engineering, including the creation of robust and reinforced walls that can withstand the weight of the rocks and maintain the integrity of the slope.

- Structural Supports

Structural supports, such as rock bolts, mesh, and shotcrete, are crucial to maintaining the stability of rock formations and slopes. These supports provide an anchoring mechanism that keeps the rocks in place, reducing the potential for unexpected or unplanned rock movements. Regular maintenance and inspection of these supports are necessary to ensure their effectiveness.

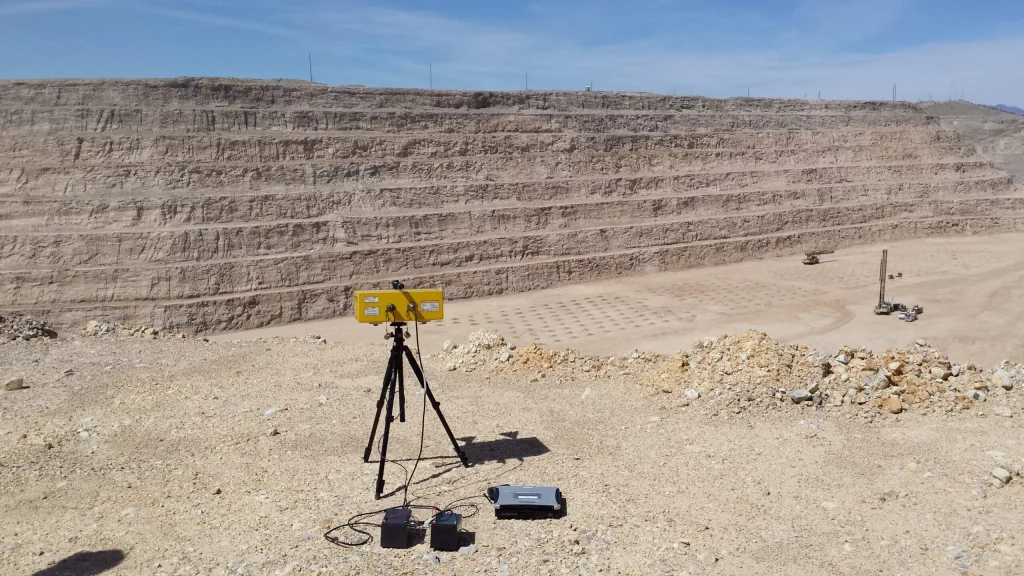

- Monitoring Systems

Aside from slope stability and structural supports, open pit mining operations must also rely on monitoring systems to detect and minimize hazards. These systems measure movements in slopes and rock formations and provide early warnings of any potential collapse or instability. Continuous monitoring enables the mining team to respond quickly to any emergent hazardous situations.

Conclusion

In conclusion, as highlighted in the preceding sections, maintaining high-standards of mining safety is crucial in the open-pit mining industry. It ensures the well-being of all workers and enhances operational efficiency while reducing the occurrence of accidents and injuries. Mining companies must implement comprehensive safety measures to minimize hazards across all mining operations. Proper training, use of Personal Protective Equipment (PPE), monitoring systems, and emergency protocols are crucial elements that should be implemented.

Additionally, blasting practices and safety measures should be prioritized to reduce risk. Mining companies must also incorporate engineering controls and safety measures to create a secure working environment for all workers. Overall, a collective effort from industry stakeholders, regulators, and employees is required to ensure mining operations balance between safety and productivity.

Key Takeaways

- Open-pit mining operations require robust safety measures to minimize risks.

- Hazards and risks associated with open-pit mining include cave-ins, equipment accidents, and exposure to dust and toxic substances.

- Essential safety measures for workers include proper training, personal protective equipment (PPE), and emergency response protocols.

- Safe blasting practices are crucial in preventing accidents in open pit mining.

- Engineering controls such as stable slope design and supportive structures can minimize hazards in open-pit mining operations