Ramps are an essential components of open pit mines. However, they can contain valuable raw materials as well, which must be recovered when the primary function of the ramp is ended. Some targets such as: respecting the fragmentation curve, containing underbreak and overbreak, and avoiding fly rocks and vibrations are similar to standard blasts of the benches.

Blasting of a ramp for pit geometry modification was a practical exercise commissioned for the exam of “blasting” at University of Bologna.

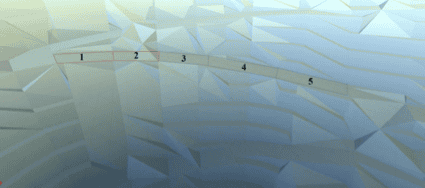

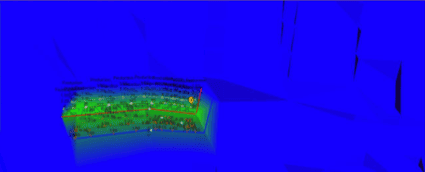

The project consisted of the demolition of the ramp at sixth level of a selected open pit mine, levelling the ground 10 m below. It could be obtained by using a sequence of five blasts applied to five different volumes. They are located in two different mineralogical zones. The density and other geomechanical properties of the rock were considered constant and are reported in Table 1.

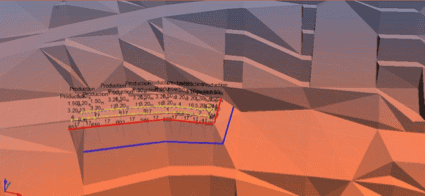

The blasts start from volume number 5, to then go back. The same explosive mix was used for all the five blasts, comprising column charge and booster, with two types of emulsion. Number of blastholes varied, based on the dimension of the volumes. After each blast, the geometry of the ramp has been changed, therefore the Digital Elevation Model must be updated.

As the demolition of the ramp progresses, new and appropriate free surfaces have to be considered.

Link to the blasting Master Course unit at UNIBO;

Professors:

Stefano Bonduà : UNIBO

Francesco Tinti: UNIBO

Students:

Veronica D’Angeli: Email UNIBO

Marco Lombardi: Email UNIBO

Camilla Lucchi: Email UNIBO

Giulia Passafaro: Email UNIBO