The mining industry is based on the blasting of rock in order to later extract the ore that is found in it. The blasting front acts as a large block that must be broken down into smaller blocks, and to do this, sometimes explosives are used.

Blasting causes the rock to move, and sometimes this can be detrimental to the precise delineation between the blocks with ore and waste regions within the resulting muckpile. The consequences of this can be loss and dilution of the ore. However, ore loss and dilution can be minimized and significant increases in profit can be reached if the movement can be controlled and accurately measured.

Usually, the mining deposits are highly heterogeneous with the ore disseminated in variable grade pockets with an economic cut-off content determined for the mine operation, and as such, any material with a lower mineralization content is designated as waste rock or waste (Domingo, Leite, Miranda, & Carrasco, 2015)

The ore is excavated and transported to the mineral processing facility while the waste is transported to a suitable disposal site. Blasting these rocks involves drilling a series of holes of a certain length and diameter, as well as a spacing-to-span ratio between them necessary to fragment and loosen the rock mass. However, the movement of the rock caused by blasting has an unfavorable effect on the separation of the ore and waste in the pile, causing the loss of ore, in case the ore is misclassified as waste and sent to the dump site; and/or dilution of the ore, in the case the waste is misclassified as ore and sent to the processing facility (Domingo, Leite, Miranda, & Carrasco, 2015).

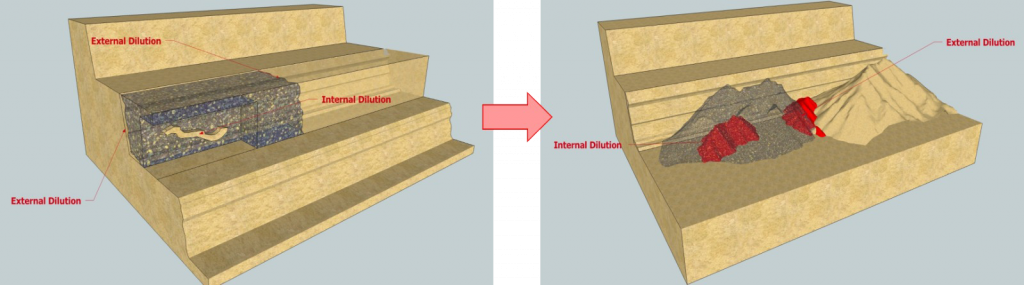

Internal dilution and external dilution

There are 2 types of dilution that can occur, known as internal dilution and external dilution. Internal dilution occurs when there is a body of non-mineralized rock within the mineralized body, which is included in the pile of dismantled mineralized material. External dilution occurs at the external contacts between the mineralized body and the non-mineralized body, which mix due to the non-favorable movement of the two bodies of material during the blasting phase (Domingo, Leite, Miranda, & Carrasco, 2015).

The internal dilution is studied and controlled according to the efficiency and detail of the geological study of the body to be dismantled. If the non-mineralized body is detected prior to the dismantling, a selective charge can be made so that the body is not fragmented, preventing the mixing of it with the mineralized material from occurring, facilitating its removal from the pile.

External dilution is studied and controlled as a function of monitoring the associated blasting parameters. The dilution in a blasting can be calculated by the ratio of the volume of material below the shear content to the total volume of the blasting (Ebrahimi, 2013)

Where:

- %Dil – Dilution percentage;

- VR – Volume of material below the cutting content;

- VT – Total volume of dismantled material.

Choked Blast

Chocked Blast, which translates to “smothered” blasting, is a term used in mining to describe blasting without a free front, where the goal is to achieve rock fragmentation by denying movement of the material in any direction.

This method although effective, has some disadvantages, one of them being the need to adjust to the fire diagram. In a bench blasting the goal is to dismantle the rock from the free front, with each detonation fragmenting and pushing the dismantled material forward, thus creating a new free front for the next detonation, until it reaches the rear of the bench.

However, in choked blasts this doesn’t happen, here the goal is to not allow the material to move, so the lack of free front increases the resistance that the material has in relation to the energy that the explosive releases. So, it is necessary to change some parameters that translate into an increase in energy. One possibility would be to decrease the distance and spacing of the mesh; another possibility would be to increase the diameter of the holes to allow for a greater amount of explosive charge. Regardless of the option chosen it is necessary that precautions be taken regarding the safety of the blasting, such as increasing the stemming to counteract the increased amount of explosive in the hole.

Timing sequencing for material segregation

Delay times in hole timing are applied for segregation of ore and waste during blasting. The general principle is that since the rock moves in the opposite direction of the timing growth, ore and waste can be segregated by controlling the detonation delay times that propagate towards the ore/waste boundary (Preece & Silling, 2016).

It is well understood that mining takes place in a geological environment and that the ore bodies are anything but regular or straight, so the use of electronic delay timing options allows a complex detonation timing of the blast and easier separation into ore and waste piles (Preece & Silling, 2016).

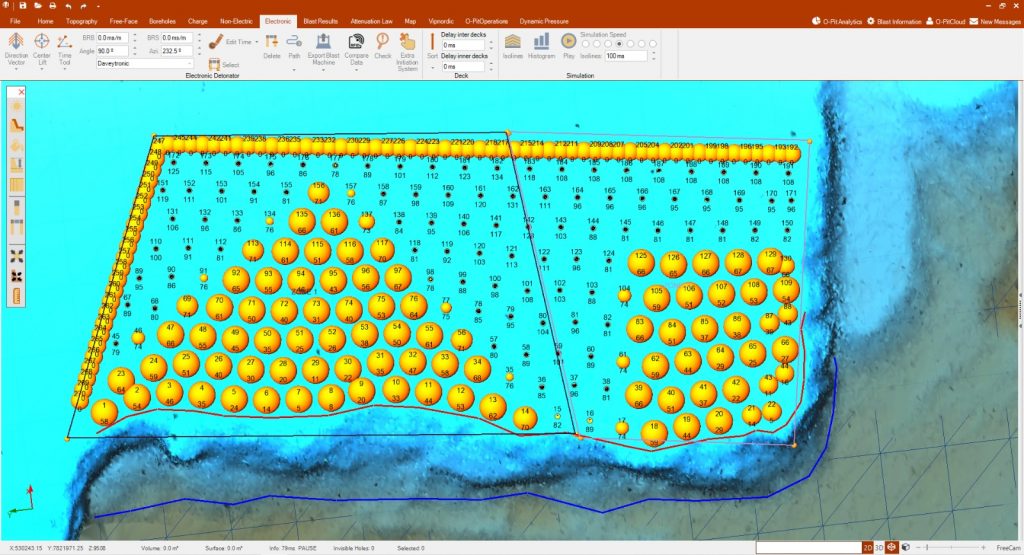

When there is a clear discontinuity between 2 grades in different zones, it is advisable that timing control is in place, which forces the creation of 2 muckpiles that are separated by the same discontinuity. In the figure 2 you can see an example of the method to be used to separate a bench that had a significant difference of 2 contents, done using O-PitSurface

O-PitSurface is a good tool for this purpose as it features a simulation tool that was used to adjust the timing of the electronic detonators that allowed the angle of change of the isolines to be placed over the content discontinuity.